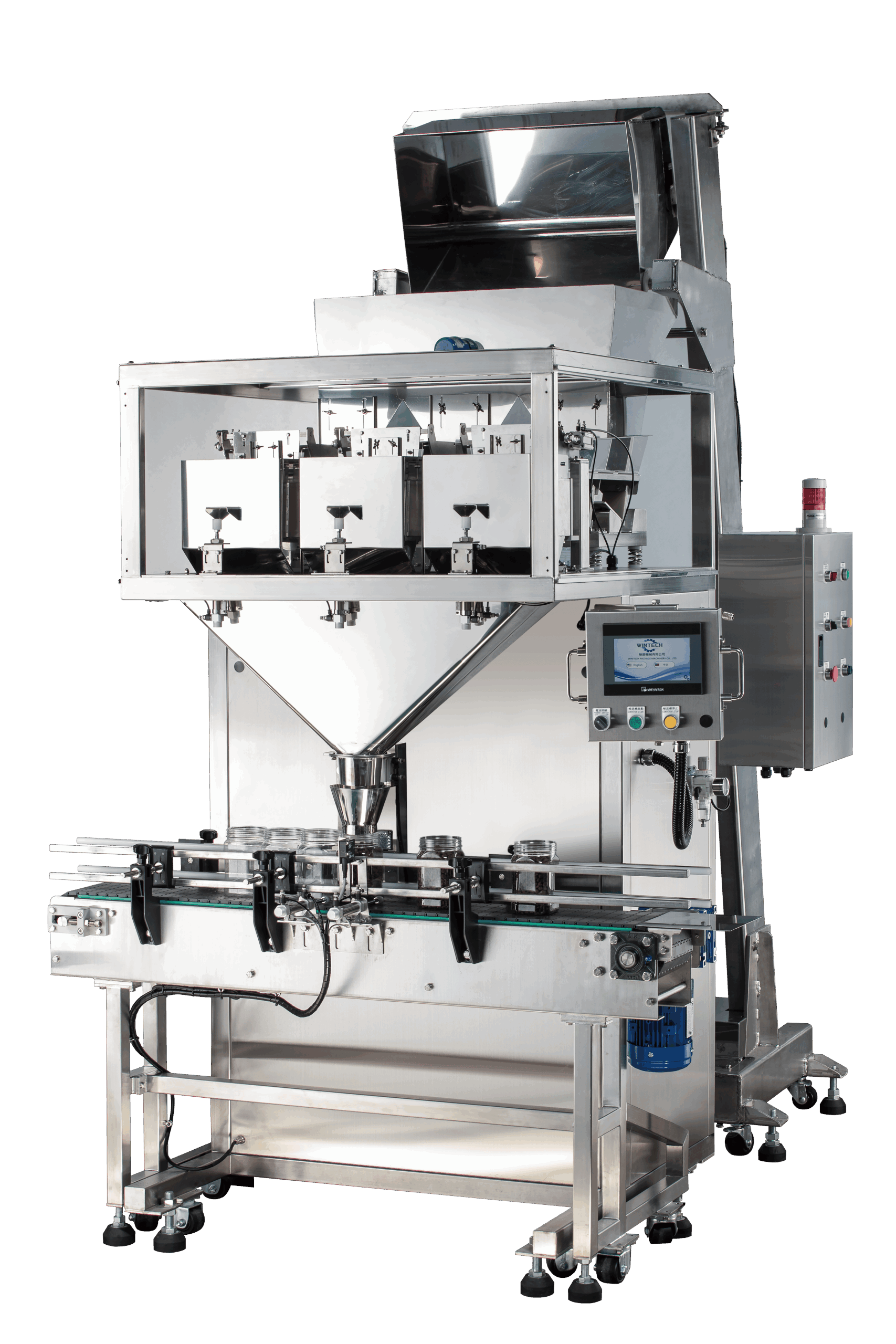

High-Efficiency Weighing × Stable Filling — The Ideal Solution for Smart Filling Production Lines

The Weigh and Fill Machine is equipped with a Japan-made PLC and a touchscreen HMI, offering intuitive operation and quick parameter setup, making it easy for even first-time users to operate. With four adjustable speeds, the system can be fine-tuned according to material characteristics, effectively improving weighing efficiency and dosing consistency.

It also features real-time error alerts and troubleshooting guidance, significantly reducing downtime and ensuring long-term stable operation.

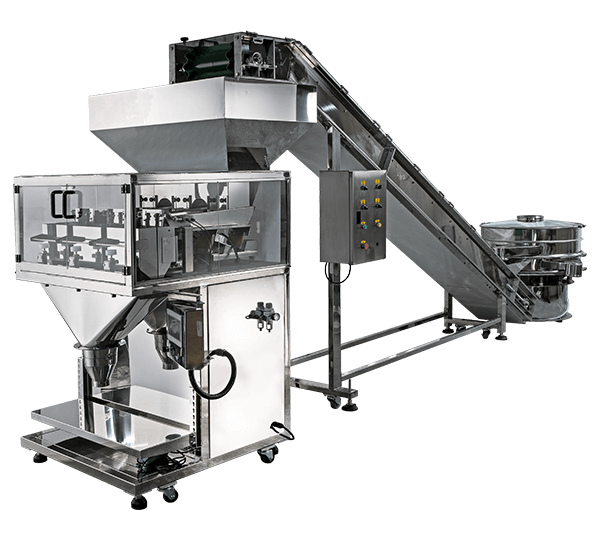

This Weigh and Fill Machine can be flexibly integrated with feeding devices, vibrating sieves, and reporting systems, enabling the creation of a versatile, automated weighing and filling process. With stable material feeding and precise dosing, it enhances operational efficiency and weighing accuracy.

By optimizing factory workflows, the Weigh and Fill Machine boosts production output and management performance, helping businesses take a step forward into smart manufacturing.

What Is a Weigh and Fill Machine?

A weigh and fill machine is an automated system designed to measure and dispense precise quantities of products into containers or packages. It uses advanced weighing sensors to ensure accuracy and consistency, making it ideal for industries such as food, pharmaceuticals, cosmetics, and chemicals.

The weigh and fill machine not only improves production efficiency but also minimizes material waste, helping manufacturers maintain quality control while reducing operational costs.

How Does a Weigh and Fill Machine Work?

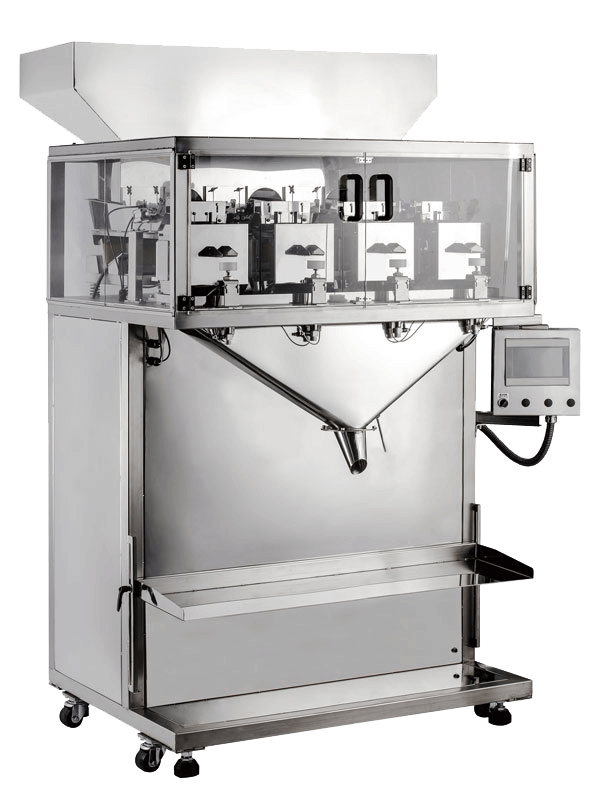

A weigh and fill machine works by combining a precise weighing system with an automatic filling mechanism.

First, the product is fed into a weighing hopper or scale that measures the exact weight needed. Once the target weight is reached, the product is released into the packaging container, such as a bag, jar, or bottle. Advanced models can automatically adjust the feeding speed, ensuring both accuracy and efficiency.

The weigh and fill machine can also be integrated into a complete packaging line with sealing, labeling, and conveying systems for streamlined production.

What Products Are Suitable for a Weigh and Fill Machine?

A weigh and fill machine is suitable for a wide range of materials, and the ideal model depends on the type of product being packaged. Generally, these machines can be classified into three main categories based on material characteristics:

Granular and Solid Products:

Items such as coffee beans, rice, nuts, candies, seeds, and pet food are perfect for multi-head or linear weighers. These models can handle free-flowing materials efficiently with high speed and accuracy.

Powder Products:

For fine materials like flour, protein powder, spices, or chemical powders, specialized weigh and fill machines with dust-proof designs and auger fillers are used to ensure clean and precise dosing.

Liquid and Paste Products:

Materials such as sauces, oils, creams, and gels require weight and fill machines equipped with piston or pump filling systems, which can maintain consistent volume and prevent spillage.

By selecting the right type of weight and fill machine according to material properties, manufacturers can achieve higher production stability and minimize waste.

Read more: 3 Pharmaceutical Packaging Types: How to Choose the Right One

Advantages of Using a Weigh and Fill Machine

A weigh and fill machine provides several key benefits that make it essential for modern manufacturing and packaging processes:

- High Accuracy: Ensures every package contains the correct amount of product, reducing waste and maintaining product consistency.

- Increased Efficiency: Automates weighing and filling, significantly speeding up production compared to manual labor.

- Versatility: Adjustable for various product types—granules, powders, liquids, or pastes—making it suitable for multiple industries.

- Cost Reduction: Minimizes labor requirements and material waste, lowering overall production costs.

- Hygiene and Safety: Reduces human contact with materials, meeting food-grade and pharmaceutical hygiene standards.

- Easy Integration: Can be seamlessly connected with conveyors, sealing, and labeling machines for a fully automated line.

- Consistent Quality: Maintains precise and repeatable filling results across every production batch.

CONTACT

Contact WINTECH for tailored smart manufacturing solutions. Let’s create efficiency together!