Wintech is proud to announce its participation in the 2025 Taipei International Packaging Industry Show, where it will present a full line of automated, high-precision packaging equipment tailored for the food, health supplement, pharmaceutical, and cosmetics industries. Key machines on display will include the AF2000 Auger Powder Filling Machine, AF2100 Corner Pouch Packaging Machine, AF100 Micro Auger Filler, Vibratory Weigh Filling Machine, and the WT-300 Series Checkweigher—designed to help businesses improve production efficiency, accuracy, and quality control.

Precision Filling Systems for Powder Applications

🔹 AF2000 Auger Powder Filling Machine

Ideal for medium- to large-volume filling of powders such as protein, milk, seasoning, and cosmetic ingredients, the AF2000 supports a filling range of 50–2000g with ±0.5–1% accuracy. It is powered by a Japanese servo motor and PLC system, with 60 product memory slots for fast changeovers and efficient line management.

🔹 AF2100 Auger Corner Pouch Packaging Machine

Engineered for small-dose powders like instant drinks, matcha, or nutraceuticals, the AF2100 delivers 3–10g filling with 3–5% accuracy and ≥30 packs per minute. The machine supports attractive corner-sealed pouch formats, enhancing product presentation and shelf appeal.

🔹 AF100 Micro Auger Filler

Designed for micro-dosing precision, the AF100 is suitable for food additives, fine supplements, or pharmaceutical powders. It offers 0.1–10g dosing with ±1–5% accuracy, making it ideal for small-batch, high-accuracy applications.

Efficient Granule Filling & Quality Assurance

🔹 Vibratory Weigh Filling Machine

Perfect for granular materials like nuts, coffee beans, dried fruit, and snack products, this solution handles 50–3000g with ±0.2–1% accuracy. It features 60 memory programs, intuitive touch-screen control, auto feedback, and seamless line changeover.

🔹 WT-300 Series Checkweigher

Built for high-speed inspection, the WT-300 offers a weighing range of 1–150g, precision up to 0.05g, and throughput of up to 150 pcs/min. It includes user-friendly HMI, auto-calibration, historical log tracking, and network data transmission. Optional metal and vision inspection modules are also available.

Driving Smart Manufacturing with Automation

For over a decade, Wintech has specialized in packaging solutions that combine precision, reliability, and ease of integration. From powder and granule filling to checkweighing and data tracking, Wintech delivers complete systems that help manufacturers transition to smart, automated production.

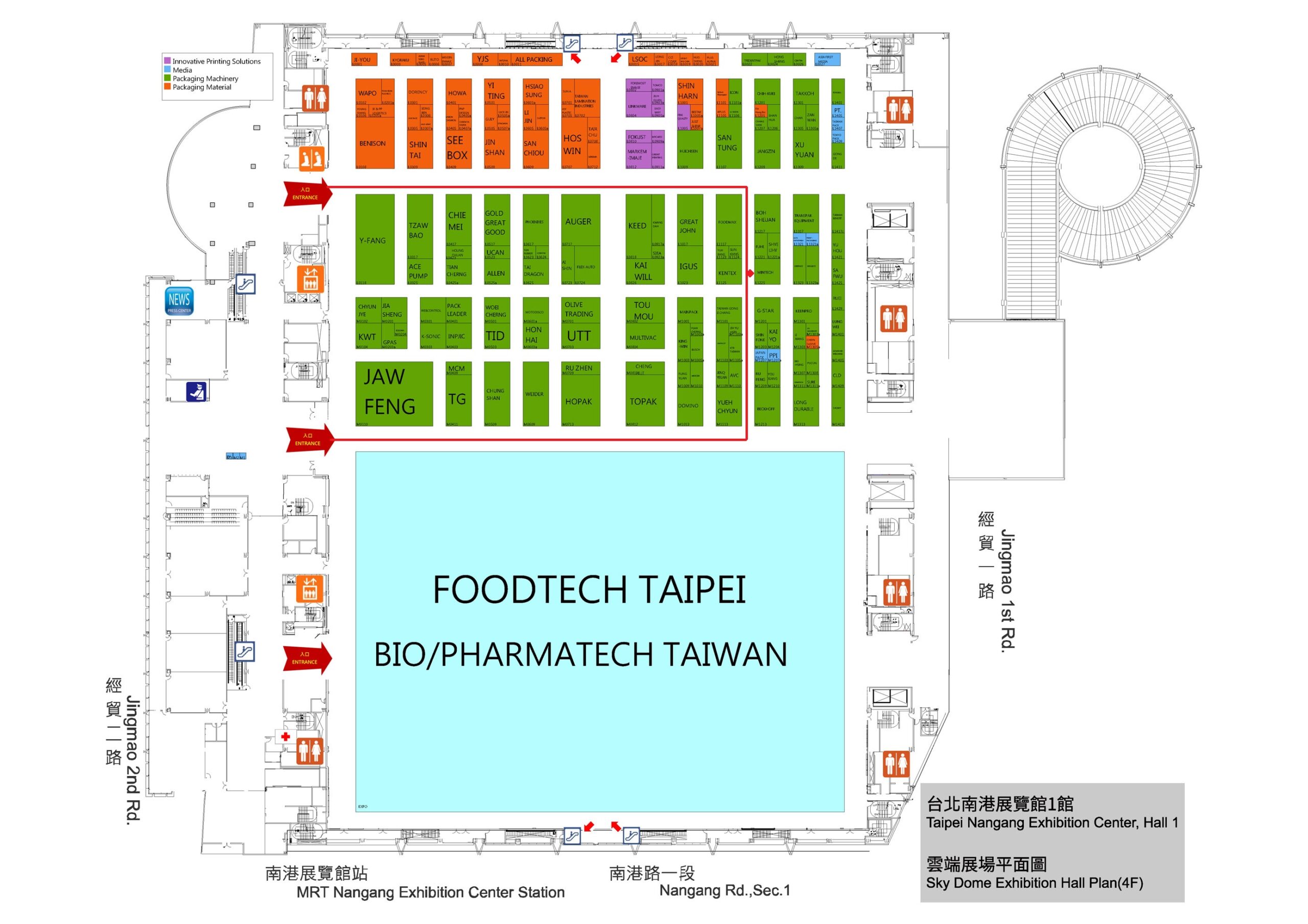

📍Exhibition Date: June 25 – June 28, 2025

📍Exhibition Venue: Taipei Nangang Exhibition Center

📍Wintech Booth Number: L1225

Visit Wintech at the show to discover how our machines can boost your line efficiency, improve packaging quality, and support your growth in competitive markets.