-

Model:WT-300 series

Weighing Range*1:1g~150g

Resolution:0.05g

Dynamic Accuracy *2:0.05g/0.1g

Max. Sorting Speed:150pcs/min

Conveyor Belt Width:120mm

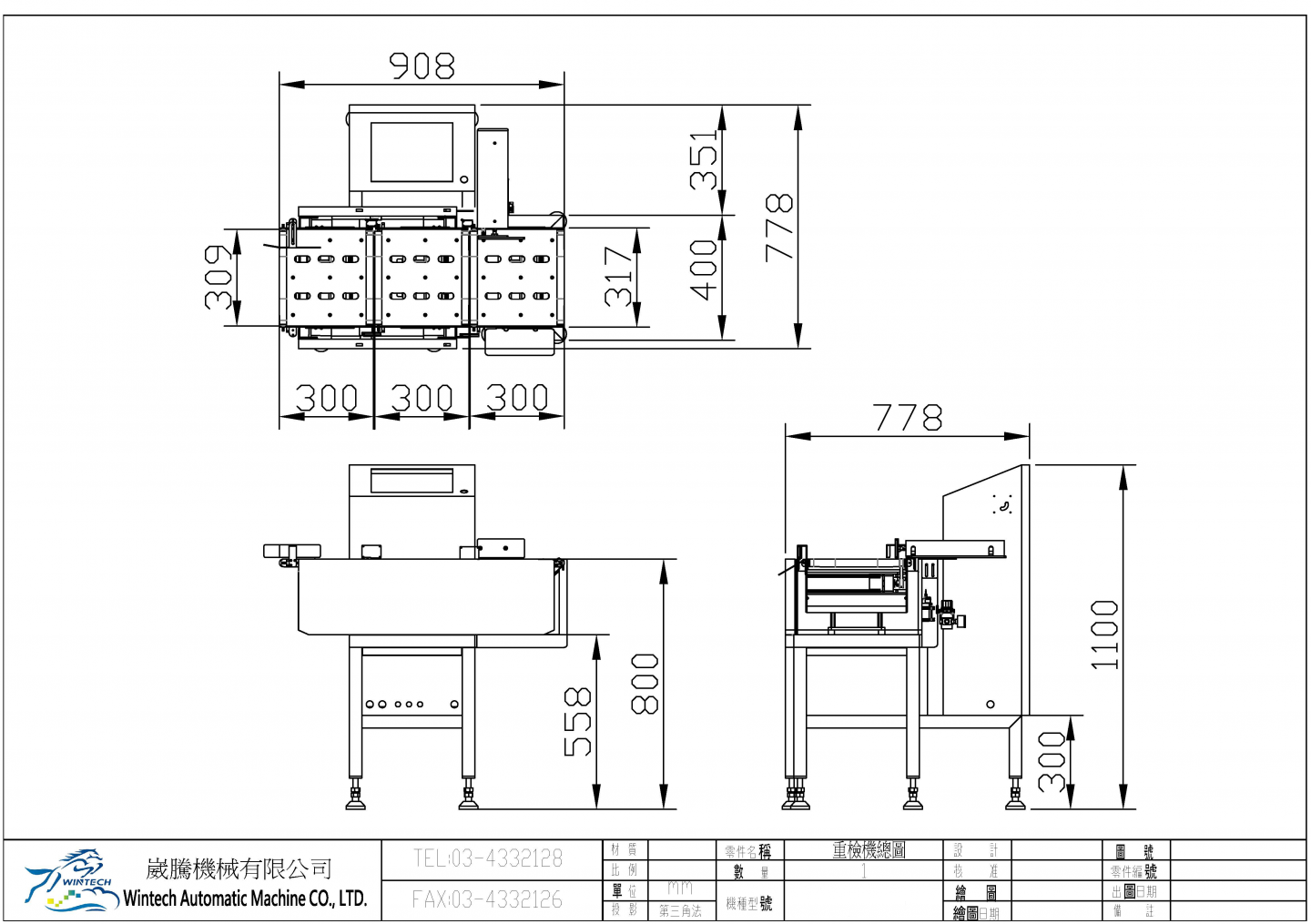

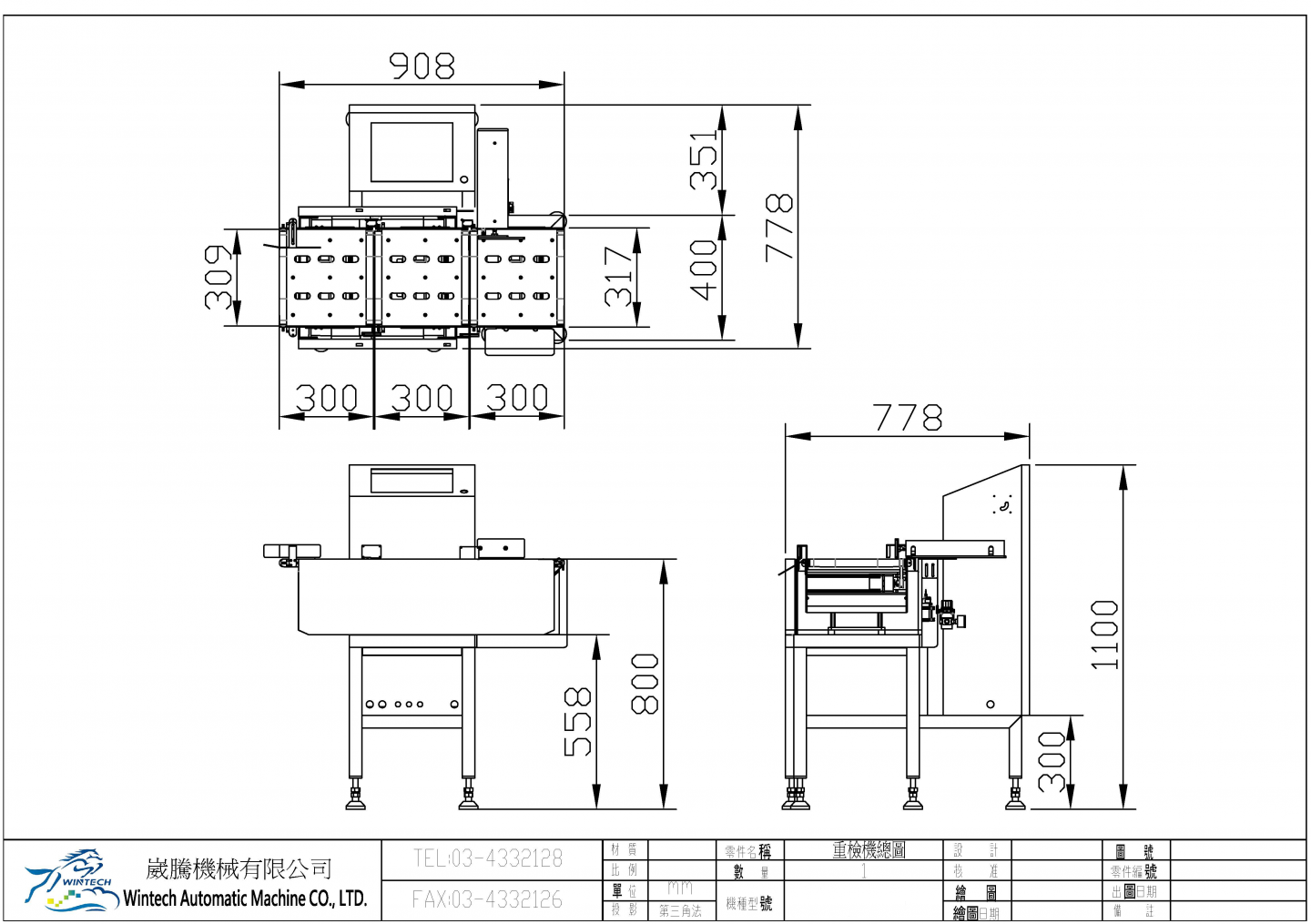

Conveyor Length:300mm

Monitor:10-inch TFT color LCD display

Memory Module:30 set

Communication Function:Modbus RTU , RS-232C/485 /422,Ethernet,EtherCAT

Working Environment:Temperature: 0°C~40°C,humidity less than 80% (no condensation)

Power:AC220V,AC220V, single/three phase, 50/60HZ

Option Parts:Label printers, barcode scanners

*1: If larger scale is required, please contact service personnel.

*2: The dynamic accuracy will be affected based on the actual measured item, weight, sorting speed and on-site installation environment.

◊Historical record function

♦Operation history:Record system operation message

♦Event history:Record system error messages to help engineers eliminate errors

♦Weight history:Production history records, recorded data are: date, time, product name, ID, weight, judgment value

◊Smart HMI function

♦Easy to operate:Parameter setting and weight calibration can be completed in 2 steps

♦Smart reminder window:Let the operator quickly eliminate the problem.

♦Convenient for product changeover:Built-in multiple product parameters can quickly replace product parameters and improve production efficiency.

◊Production history network transmission function

The production history in EXCEL (CSV) format is automatically output and sent to the specified path on the computer.

♦Production resume data analysis to improve production efficiency.

♦Replacement of manual meter reading errors and implement electronic data.

♦Automate data transfer by eliminating the need to plug and unplug USB .

Note: (This function requires its own computer, HUB, ethernet cable, EXCEL software)

◊Historical record function

♦Operation history:Record system operation message

♦Event history:Record system error messages to help engineers eliminate errors

♦Weight history:Production history records, recorded data are: date, time, product name, ID, weight, judgment value

◊Smart HMI function

♦Easy to operate:Parameter setting and weight calibration can be completed in 2 steps

♦Smart reminder window:Let the operator quickly eliminate the problem.

♦Convenient for product changeover:Built-in multiple product parameters can quickly replace product parameters and improve production efficiency.

◊Production history network transmission function

The production history in EXCEL (CSV) format is automatically output and sent to the specified path on the computer.

♦Production resume data analysis to improve production efficiency.

♦Replacement of manual meter reading errors and implement electronic data.

♦Automate data transfer by eliminating the need to plug and unplug USB .

Note: (This function requires its own computer, HUB, ethernet cable, EXCEL software)