In the rapidly growing tea market, tea bags are not merely packaging—they are an extension of product flavor, cost control, and brand identity. For food manufacturers and procurement specialists, understanding the characteristics and ideal applications of various types of tea bags is key to enhancing product competitiveness.

This article introduces five mainstream types of tea bags tailored to factory needs, analyzing their pros and cons while recommending the semi-automatic SF1002 machine to help optimize your production process.

The Origin of Tea Bags

Tea bags were invented by accident in the early 20th century. In 1908, a New York tea merchant named Thomas Sullivan sent tea samples to his customers in small silk pouches instead of traditional tins. Many recipients mistakenly steeped the tea directly in the pouch, discovering that it was a convenient and mess-free way to brew tea.

This unexpected usage quickly gained popularity, leading to the development of modern tea bags. Over time, tea bags evolved from silk to paper and, more recently, to biodegradable and plastic-free materials, reflecting changes in consumer preferences for convenience, quality, and sustainability.

Why Tea Bag Types Matter?

Choosing the right tea bag affects tea leaf infusion and flavor release, brand eco-image and consumer goodwill, packaging material compatibility with machines, and production costs and line efficiency.

The choice of a tea bag impacts not only the brewing experience but also purchasing costs and market performance.

What Are the Types of Tea Bags and Their Applications

Tea bags are more than just a convenient way to brew tea; they also impact brewing quality, flavor release, brand image, and even production efficiency.

For manufacturers and buyers, understanding the different types of tea bags and their ideal uses is crucial for balancing taste, cost, and market demand. Below, we’ll introduce the five most common tea bag types.

Classic Paper Tea Bags: Affordable and Widely Used

This type of tea bag offers high cost-performance and is a mass-market favorite.

- Pros: They have a low cost with a stable material supply and are ideal for CTC (crush-tear-curl) or instant tea. They are easy to integrate with automatic or semi-automatic machines.

- Cons: They have limited capacity and permeability, making them not ideal for whole-leaf teas. Their heat-sealed areas may contain plastic, which makes them less eco-friendly.

- Best for: Supermarket teas, convenience store instant teas, and bulk export orders.

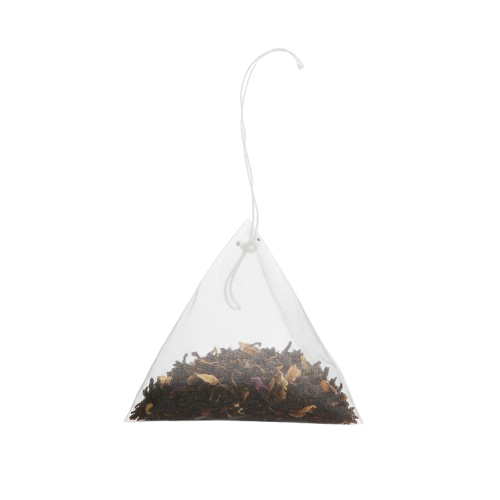

Pyramid Tea Bags: Better Flow, Better Flavor

Pyramid tea bags use three-dimensional packaging that enhances aroma.

- Pros: They are ideal for high-quality whole leaf and herbal teas. They offer high infusion efficiency and a natural taste. Their visually appealing shape enhances brand positioning.

- Cons: They have higher material and forming equipment costs. The process is more complex and requires specialized machines.

- Best for: Premium tea brands, gift sets, and organic herbal tea lines.

Silken & Biodegradable Mesh Tea Bags: Premium and Sustainable Options

These tea bags are an elegant and eco-conscious packaging choice, often made with nylon or PLA materials.

- Pros: They offer excellent infusion flow, enhancing the flavor experience. They promote brand sustainability and align with ESG trends. They are ideal for high-value blends and functional teas.

- Cons: They have higher material and production costs. They require compatible sealing processes and packaging technologies.

- Best for: High-end retail, international markets, and corporate gifts.

Double Chamber Tea Bags: Improved Infusion with Classic Design

Double chamber tea bags feature two connected compartments that allow better water circulation than traditional flat tea bags.

- Pros: They improve tea extraction compared to single-pocket paper tea bags. They are typically made from paper-based materials and remain cost-effective for large-scale production. They are compatible with high-speed packing lines.

- Cons: They still offer limited space for full leaf expansion. They are commonly used with broken tea leaves or fannings rather than whole leaves. Their appearance is more functional than premium.

- Best for: Mass-market black tea products, breakfast tea blends, and brands seeking a balance between brewing performance and production efficiency.

Reusable Tea Bags / Tea Infusers: Sustainable and Refillable Solutions

Reusable tea bags and tea infusers are designed for repeated use and support loose leaf tea brewing.

- Pros: They significantly reduce single-use waste. They allow consumers to customize tea blends and portion sizes. They are available in durable, food-grade materials such as silicone, stainless steel, or cloth.

- Cons: They require cleaning after each use. They are less convenient for on-the-go consumption. They are not suitable for commercial tea bag packaging.

- Best for: Loose leaf tea enthusiasts, home brewing, cafés, and environmentally conscious consumers.

| Type of Tea Bag | Pros | Cons | Best For |

| Classic Paper Tea Bags | Low cost and easy to produce. | Limited flavor and leaf expansion. | Mass-market and everyday teas. |

| Pyramid Tea Bags | Better water flow and aroma. | Higher material and equipment cost. | Premium and specialty teas. |

| Silken & Biodegradable Mesh Tea Bags | High infusion quality and eco-friendly options. | Higher material cost. | High-end and sustainable tea brands. |

| Double Chamber Tea Bags | Improved infusion over flat paper bags. | Still limited space for whole leaves. | Black tea and high-volume production. |

| Reusable Tea Bags / Tea Infusers | Reusable and reduces waste. | Requires cleaning and handling. | Loose leaf tea and home use. |

How to Choose the Right Tea Bag for Your Product?

Cost-first:

Recommended to choose Classic Paper Tea Bags or Double Chamber Tea Bags, which offer stable quality at a low cost and are suitable for mass production.

Quality-focused:

Pyramid Tea Bags or Silken Mesh Tea Bags are the recommended choice for better infusion performance and enhanced flavor release.

Sustainability-driven:

Choose Biodegradable PLA Mesh Tea Bags or Reusable Tea Bags, ideal for brands prioritizing environmental responsibility.

Small/Medium Production:

Use Loose Tea with the SF1002 Semi-Automatic Filler System, which provides flexibility for small batches, custom blends, or specialty tea products.

(Read more: Which Types of Packaging Materials Are Best for Your Product?)

Recommended Equipment: SF1002 Semi-Automatic Tea Filling Machine

The SF1002 is ideal for filling loose tea into pre-made bags, especially for medium-scale production, test runs, or OEM customization. It is suitable for free-flowing tea types like crushed, herbal, or fruit teas. It is compatible with pre-made bags like three-side seal and back-seal for precise filling and works with sealing machines for flexible post-filling packaging. This machine reduces automation investment cost, making it ideal for flexible production lines.

Frequently Asked Questions (FAQ)

Choosing the right tea bag format and equipment often raises practical questions for manufacturers and buyers. To help you make informed decisions, we’ve compiled answers to some of the most common inquiries about different types of tea bags.

Q1: Can SF1002 be used for pyramid tea bags?

A: No. The SF1002 is designed for filling loose tea into pre-made bags, such as three-side seal bags. It does not have pyramid forming or heat-sealing capabilities, as pyramid tea bags require dedicated forming equipment.

Q2: Is SF1002 a fully automatic machine?

A: No. SF1002 is semi-automatic. Bags are placed manually, filled automatically, and sealed with an external sealer, making it ideal for small to medium production or pilot runs.

Q3: Which tea bag is recommended for a sustainability-oriented tea line?

A: PLA biodegradable mesh tea bags or plastic-free sealed filter paper with FSC-certified packaging and a minimalist design are recommended for sustainable packaging trends.

Q4: Are biodegradable tea bags better than traditional paper tea bags?

A: Biodegradable tea bags are more eco-friendly since they use plant-based or compostable materials like PLA mesh or plastic-free filter paper. They align with sustainability trends and appeal to eco-conscious consumers. However, traditional paper tea bags remain more cost-effective and widely available, making them a practical choice for mass-market products.

Q5: Which tea bag type is most suitable for premium or gift teas?

A: Pyramid tea bags and silken or biodegradable mesh tea bags are the most suitable for premium or gift teas. Their three-dimensional shape allows whole leaves to infuse fully, delivering better flavor and aroma, while the elegant appearance enhances brand value and consumer appeal.

Conclusion

Choosing the right types of tea bags is not only about cost b…ning. Each option carries unique advantages and limitations.

For manufacturers seeking flexibility, the SF1002 Semi-Automatic Loose Tea Filling Machine is designed for small to medium volume packaging of broken or herbal teas and is compatible with various sealing machines, making it an efficient solution for diverse production needs.

If you’re exploring the best tea bag options or looking for the right equipment to enhance your production line, contact our team today—we’ll help you find the ideal packaging strategy for your business.

Read more: