Powder Filling Equipment

In the food and pharmaceutical industries, powder filling is a process that demands high levels of accuracy and cleanliness. Whether it’s nutritional powders, seasonings, herbal medicine powders, or protein powders, each packaging cycle must ensure consistent weight, dust control, and stable product quality.

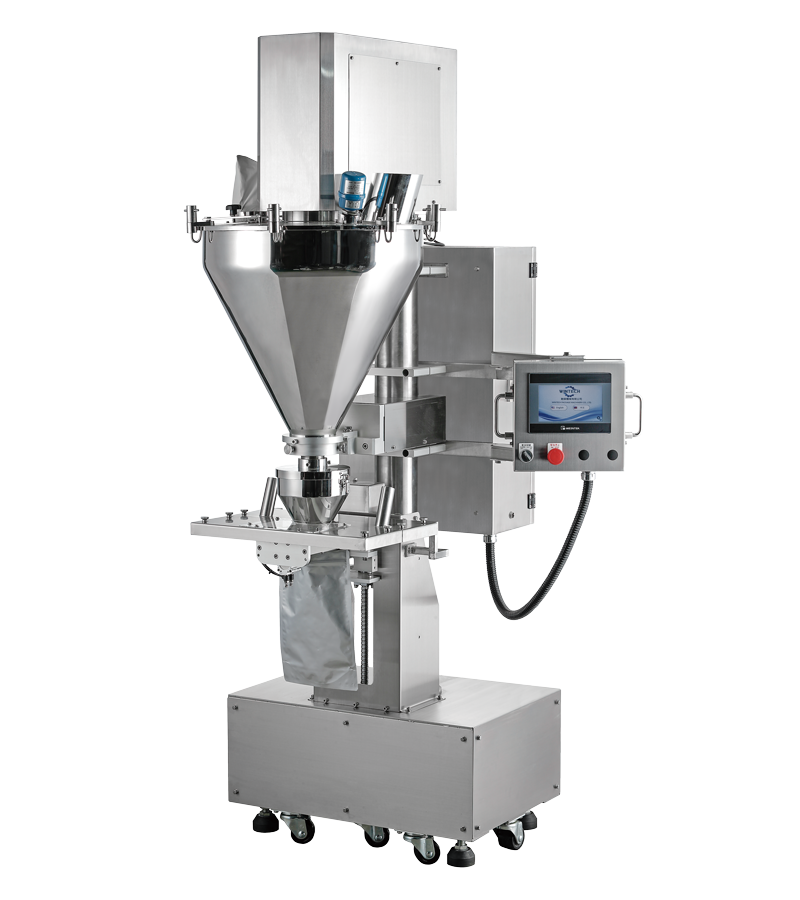

This is where Wintech Package Machinery Co., LTD.’s powder filling equipment plays a critical role. From semi-automatic standalone units to fully integrated automated lines, Wintech offers a variety of configurations to meet the needs of different production scales and packaging formats.

Home / Powder Filling Equipment

What Is Powder Filling Equipment?

Powder filling machines are designed specifically for dry powder products. They use precise dosing mechanisms to fill powders into bags or containers, preventing overfilling, underfilling, or secondary contamination. These machines are widely used in:

- Food industry (e.g., coffee powder, milk powder, spices, baking powder)

- Health and pharmaceutical sectors (e.g., vitamin powder, sachet granules, herbal medicine powder)

- Chemical and cleaning products (e.g., detergent powder, industrial powders, dyes)

Integrating powder filling equipment boosts efficiency and improves product consistency and professionalism.

Why Is Auger Filling Ideal for Powder Products?

Wintech’s core filling technology utilizes auger filling, one of the most stable and versatile methods for handling powders. The rotating screw conveys powder to the outlet, accommodating various densities, viscosities, and flow properties.

Key Benefits of Auger Filling:

- Wide applicability: Accurately fills fine powders, loose powders, and granules

- Handles poor flowability: Suitable for sticky or electrostatic powders that are difficult for gravity-fed systems

- High operational stability: Smooth filling reduces dust and clogging

- Easy maintenance and changeover: Quick replacement and cleaning of screw and hopper support multi-product lines

Wintech Powder Filling Solutions:

Reliable & Customizable

Wintech’s powder filling equipment is flexible, efficient, and customizable, going beyond automation and stability to emphasize line flexibility and scalability, while supporting hygiene-focused design and modular integration across industries.

Core Features

Modular construction

Customizable hoppers, outlets, and conveying options

Multilingual HMI

Easy-to-use interface for quick setup and batch changes

High compatibility

Integrates with existing sealers, conveyors, or full packaging lines

Hygienic design

Stainless steel contact parts meet food and pharmaceutical GMP standards

Representative Models

Ideal for premade pouch filling of small-to-medium volumes; supports screw and tube replacement; works with sealing units

Integrates film forming, filling, sealing, and optional nitrogen flushing; suitable for high-speed production of stick packs and flat pouches

Application Areas of Powder Filling Equipment:

From Seasonings to Supplements

Wintech’s powder filling solutions accommodate various powder types and properties, from free-flowing spice powders to moisture-sensitive probiotic blends. Adjustments ensure consistent packaging across product categories.

Food

Seasoning powders, protein powder, milk powder, coffee powder, cocoa powder, flour

Pharmaceuticals

Vitamin powder, probiotics, collagen, herbal powder, enzyme powder

Chemicals/Industrial

Cleaning powders, pigments, additives, cosmetic powder ingredients

Packaging types include premade stand-up pouches, stick packs, small bottles, foil packs, and alu-plastic bags. Optional features include nitrogen flushing, dust removal, and multi-stage feeding for preservation and presentation needs.

Why Choose Wintech Package Machinery Co., LTD.?

With four key commitments for worry-free implementation, Wintech has earned a loyal international client base not only through reliable equipment quality but also by resolving production pain points and offering full technical support:

- Over a decade of experience: Deep understanding of powder behavior and production needs

- Advanced customization capability: Tailored solutions based on product, capacity, and space

- Strict quality control: All machines undergo repeated testing and inspection before delivery

- Responsive after-sales service: Online support, on-site installation training, and maintenance consulting

Wintech is more than a machine supplier—it’s your long-term partner in automation and production upgrades.

Powder Filling Equipment FAQ:

Everything You Need to Know

If you’re considering investing in powder filling equipment or looking to optimize your current setup, you probably have a few questions. Below, we’ve compiled some common questions for your reference.

Q1: Can I integrate Wintech’s filler with my existing sealer?

A:Yes. Wintech’s filling machines are highly compatible with existing sealers and conveyors—no need to alter your entire line.

Q2: Is auger filling suitable for low-flowability herbal powders?

Yes. Auger systems can handle very fine or sticky powders with dust collection and anti-static options to reduce clogging and spillage.

Q3: Do I need separate machines for stick and flat pouches?

If using roll stock film, the AF2100 can handle multiple pouch types via automatic parameter switching.

Conclusion

Choosing the right powder filling equipment is essential for ensuring product quality, operational efficiency, and scalability in today’s competitive markets.

Looking for a reliable powder packaging solution? Contact Wintech for technical consultation and catalogs! We offer sample testing, trial runs, and customized line planning to help your product go from R&D to mass production efficiently and safely.